Plastic rotomolding is really a approach used to condition and create plastic-type material elements, factors, and products. This method has been in existence for decades and is still traditionally used nowadays as it is inexpensive, productive, and can generate higher-top quality items that both are durable and eye appealing. Let us consider a closer inspection in the Plastics Rotomolding process and the way it operates.

Review of the procedure

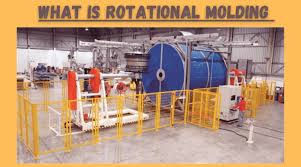

Rotomolding starts off with melting plastic-type pellets or powder inside an cooker-like unit referred to as a rotational molder. The melted fabric will then be placed in to a hollow mold which happens to be then rotated on two axes in a cooker-like holding chamber. As the mold rotates, the dissolved materials jackets the within the mold evenly. Pressure is likewise applied during this time to make sure that all sides in the hollow mold are properly layered with plastic material. After many minutes or so, the molten plastic-type cools down and solidifies into its ideal shape.

Great things about Rotomolding

The largest benefit of rotomolding is it can produce challenging styles easily and expense efficiently when compared with other production functions for example injection molding or blow molding. Rotomolded products can also be created to be extremely strong and durable as they are made out of one single part of substance causing them to be well suited for making such things as play ground devices or automobile components that need sturdiness and strength. Furthermore, because rotomolders use a lot less power than other producing operations, these are more eco friendly at the same time.

Programs for Rotomolding

Rotomolding has lots of apps in a variety of sectors including vehicle, medical, aerospace, design, packaging, toys and games, household furniture and many more. You can use it to make a assortment of products for example gas tanks for automobiles or leisure time automobiles sizeable storage space tanks custom made playground products health-related products kayaks elaborate planters patio furniture customized product packaging options sports products such as baseball backboards or ice hockey goals huge rubbish cans vessel hulls floatation products business tires and casters toy numbers pallets for shipping boxes insulated storage containers for food items safe-keeping/move jerry containers for energy safe-keeping/move and much more!

Conclusion:

As you can see from this summary write-up on plastic-type rotomolding, this method has lots of advantages over standard production functions for example increased productivity, cost savings, ecological friendliness and sturdy items that are attractive. With so many different apps in various industries around the world from auto to medical to aerospace – it is no wonder why plastic material rotomolding has become preferred right now! If you’re looking for the best inexpensive strategy to produce solid yet attractive items – think about offering plastic material rotomolding a try!